In a significant enhancement to Kochi’s infrastructure, Prime Minister Narendra Modi on Tuesday (25 April) inaugurated the first phase of the Kochi Water Metro- India’s first “Water Metro” service.

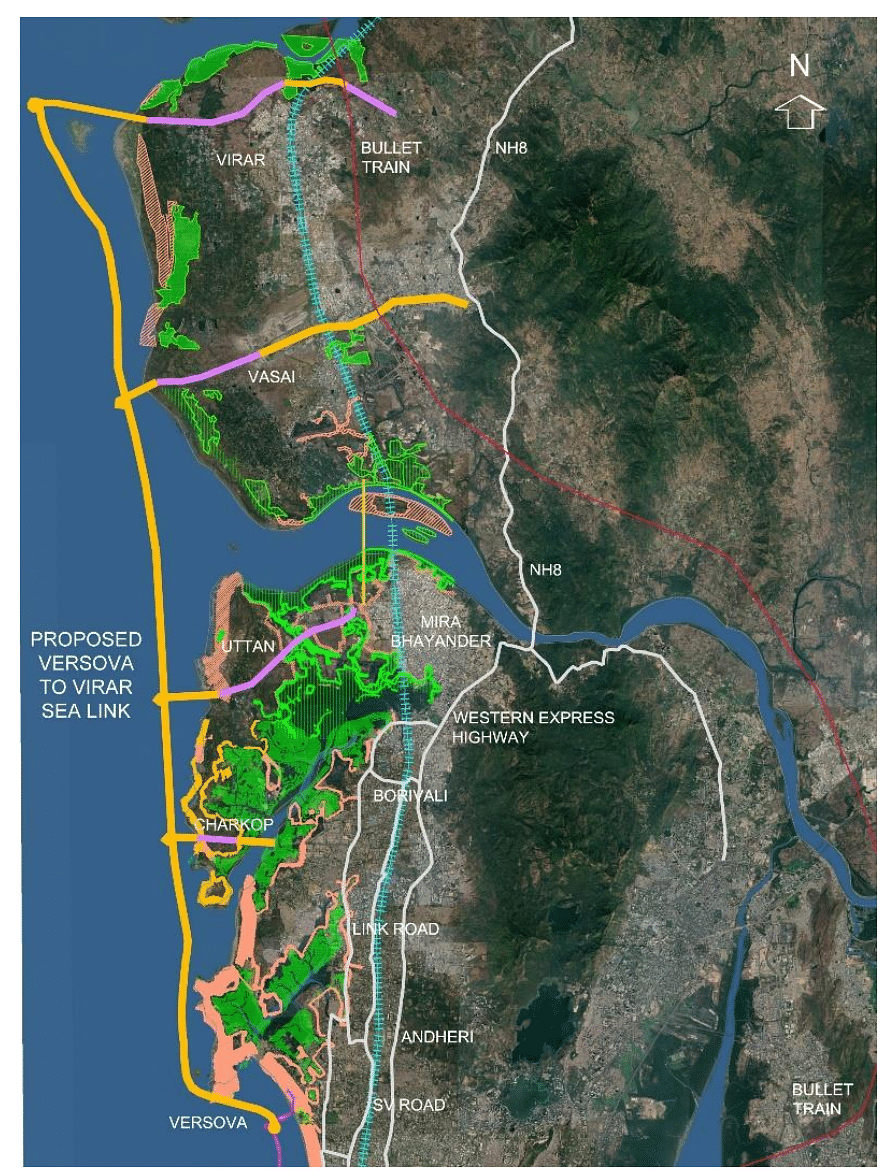

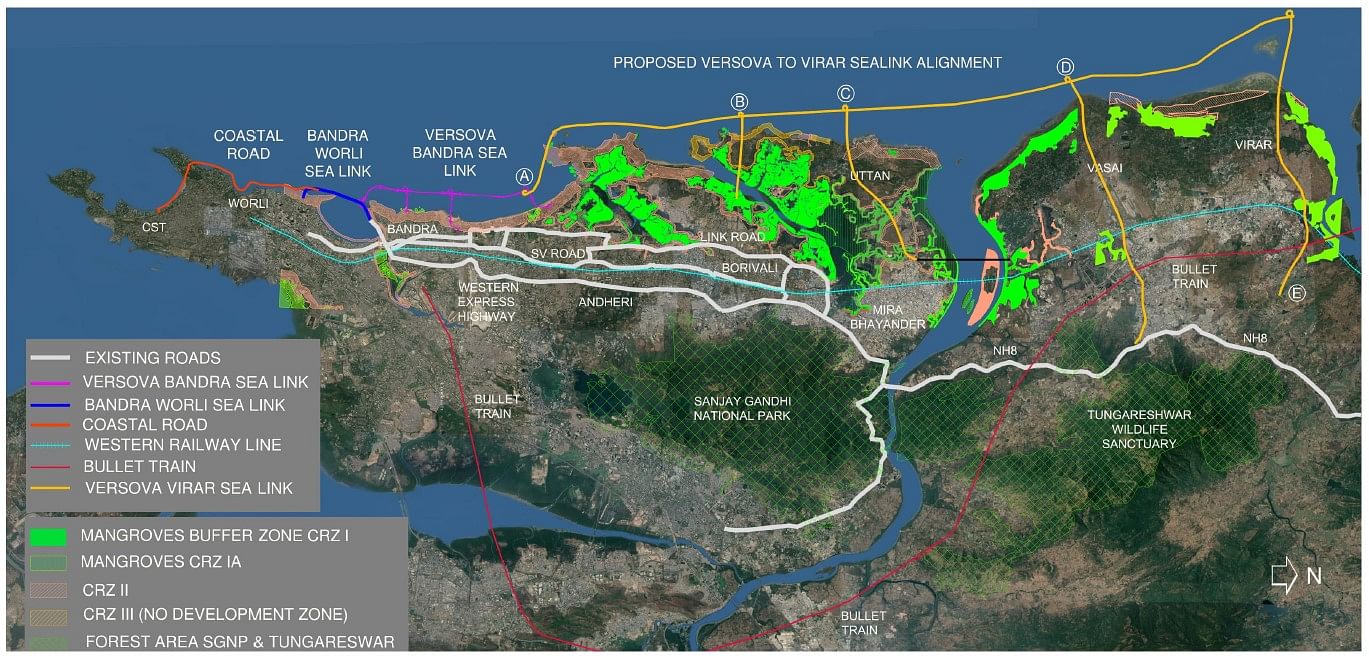

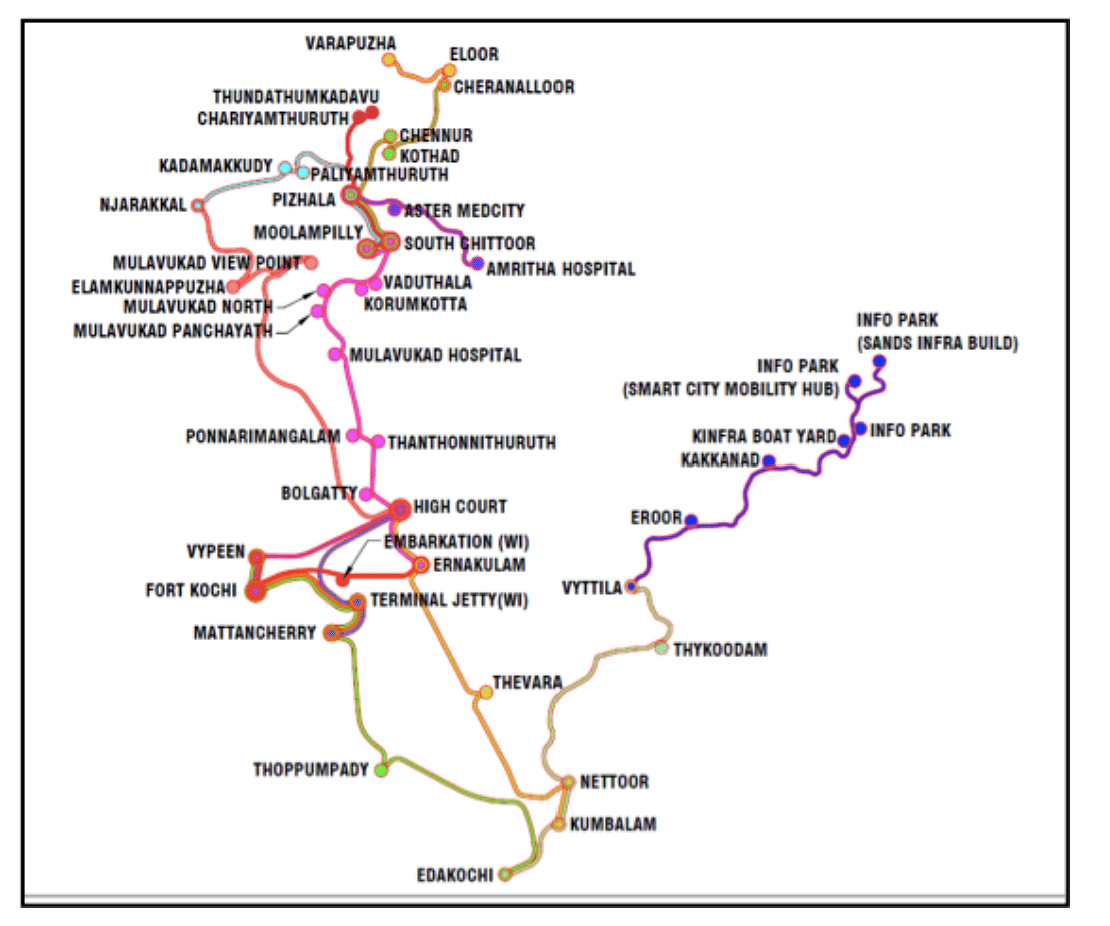

The Kochi water metro project envisage connecting 38 terminals spread across 10 islands in and around Kochi with a fleet of 78 fast, electrically propelled hybrid ferries.

The water metro will operate on water bodies like any other ferry or traditional boat service, but with modern facilities, enhanced safety and security measures.

Kerala Chief Minister Pinarayi Vijayan termed the Kochi Water Metro as a “dream project” of the state that would accelerate the growth and development of Kochi.

“The world-class #KochiWaterMetro is setting sail! It is Kerala’s dream project connecting 10 islands in and around Kochi. Exciting times are ahead for our transport and tourism sectors!” the CM tweeted.

Why a Water Metro

Kochi is the largest city in the south Indian state of Kerala and the second largest along India’s western coastline, after Mumbai.

The city sits within a complex estuarine system comprising Lake Vembanad and the many rivers flowing into the lake, including the Periyar and Muvattupuzha rivers.

Inland water transport was once the primary means of freight and passenger transport on the Vembanad lake.

At present, the Kerala Water Transport Department operates around 200-odd boat services from Kochi to nearby islands. Apart from the water transport department, there are stray services operated by private players.

However, these services have seen minimal investment and technology upgrade and have often faced the criticism for being short of facilities and safety measures.

As such the government planned Kochi water metro for which the Detailed Project Report (DPR) was approved in December 2015. The project since then has been delayed due to various reasons and has been finally launched today.

Routes And Terminals

Kochi Water Metro is an integrated water transport project which will provide intermodal connectivity between the bus terminal and the metro network.

The project is intending to utilise the existing water ways in and around Kochi and comprises of 15 identified routes over 76 route kilometres.

In the first phase, the water metro will operate with eight electric-hybrid boats on two routes: High Court to Vypin and Vyttila to Kakkanad. The anticipated journey time on both routes is around 20-25 minutes.

The commercial operation of water metro boat services will begin on 26 April.

Project Funding

In 2016, the approximate cost of the project had been pegged at Rs 747 crore which has since been revised to Rs 1,136 crore.

This amount includes a long-term soft loan of Rs 579 crore from German funding agency Kreditanstalt für Wiederaufbau (KfW) under the Indo-German financial cooperation and direct investment from the state government.

The Kochi Water Metro project will be operated and maintained by the Kochi Water Metro Limited (KWML).

Kochi Water Metro Limited has been formed as an Special Purpose Vehicle (SPV) with 74 per cent shareholding of Kerala government and 26 per cent by Kochi Metro Rail Limited (KMRL).

Integrated With Kochi Metro

India’s first water metro service will be integrated with the Kochi metro rail, which has been operational since 2017.

Passengers can travel in both Kochi metro and water metro using the “Kochi 1” card. They can also book the tickets digitally.

While the interiors of the boats are designed much like in Kochi Metro, in the same colour scheme, boat terminals, passenger entry and exit gates, ticket counters and safety measures mirror the features of the metro rail service.

All jetties feature electronic display boards about boat service. Announcements will be made in English, Hindi and Malayalam when the services are operating in full swing. Passenger entry and exit to boats, with air-conditioned cabins, are similar to the system in Kochi metros.

Boats

– The water metro will have 78 eco-friendly boats for passenger service – 23 of them will have capacity of 100 passengers and the remaining 55 are meant for 50 passengers.

– The boats constructed by Cochin Shipyard Limited (CSL), are hybrid and battery-powered.

– The ferries use lithium titanate oxide (LTO) batteries which are considered the latest and safest in battery technology, and are capable of fast charging. They can be charged in 10 to 15 minutes’ time, while passengers are alighting or boarding.

– The ferries would have diesel-powered generator back up, which will take over their operation automatically, in the event of any failure of the battery system.

– Each boat costing Rs 7.3 crore have aluminium-catamaran hull and is designed to achieve a speed of 8 to 11 knots, which is considerably faster than conventional ferries in operation in Kerala.

– The air-conditioned ferries will have large windows which will offer great views of Kerala’s famed backwaters and the banks, for passengers.

– The ferries are designed to create very less waves over the narrow channels even at high speed and would provide commuters a silent mode of transport.

– An automatic boat location system will continuously monitor their position from the Operating Control Centre (OCC) at Vytilla Mobility Hub.

– The modern, state of the art, Boats have a ramp facility for the physically-handicapped, feeding chamber for mothers, mobile recharge facilities and modern safety features, including automatic boat locating system and passenger control system.

– The electric-hybrid boats being used for the service have already gained international attention. Kochi Water Metro has won the Gussies Electric Boat Awards, the international award for electric boat.

– Also, the 38 ferry terminals will have floating jetties, making the ferries disabled and elderly friendly.

– Floating pontoons that keep the boat at the same level during high tide and low tide are the specialty of Kochi Water Metro.

The cost-effective and secure journey in water metro would help people to reach their respective destinations without being stuck in traffic snarls and is expected to give a big boost to the tourism sector in Kochi backwaters, apart from giving a modern transport facility for people living on islands on the outskirts of Kochi.

Once completed, Kochi water metro would be the largest centrally controlled urban water transport system in the world.