Beijing on Monday (3 July) imposed restrictions on exports of two obscure yet crucial metals — gallium and germanium — in an escalation of the trade war on technology with the US and Europe.

Starting 1 August, the Chinese Ministry of Commerce said Gallium and germanium, along with their chemical compounds, will be subject to export controls, a move it called essential to “protect national security and interests”.

Exporters for the two metals will need to apply for licenses from the commerce ministry if they want to start or continue to ship them out of the country, and will be required to report details of the overseas buyers and their applications, it said.

While the ministry refrained from providing specific explanations for the newly imposed restrictions, an editorial in the state-owned China Daily following the announcement strongly criticized the Netherlands for its export controls on semiconductor components.

The Dutch government announced on Friday measures that will prevent ASML Holding NV — a company with a near-monopoly on the machines needed to make the most advanced semiconductors — from selling some of its machines to China.

What Are Gallium and Germanium?

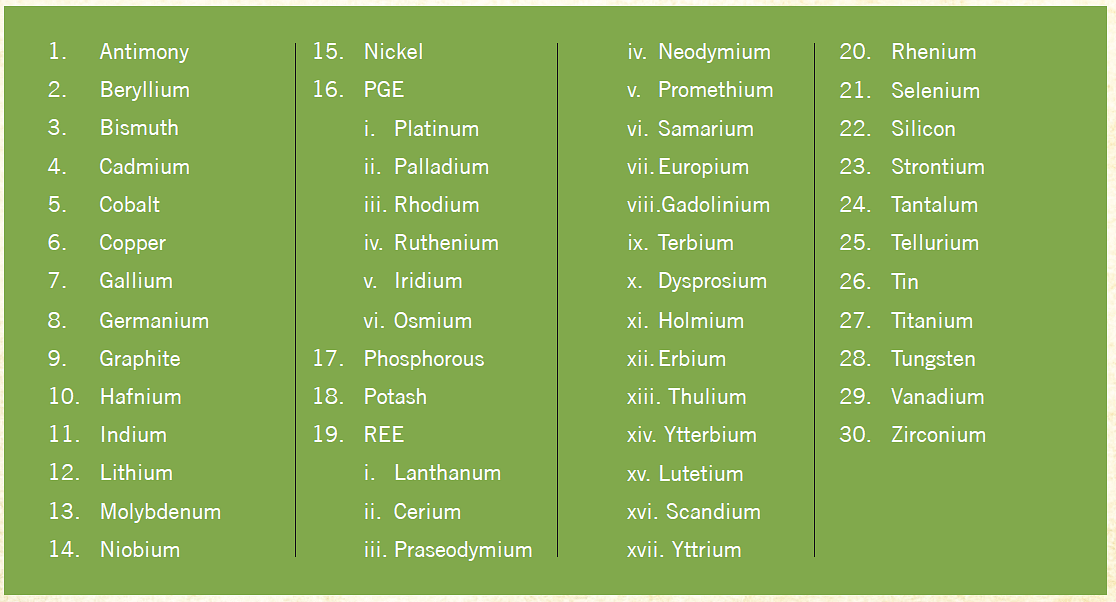

Gallium and germanium are strategic elements predominantly used in electronics. Both are byproducts from processing other commodities such as coal and bauxite, the base for aluminum production.

Gallium-based compounds, such as, Gallium arsenide (GaAs) and Gallium nitride (GaN) are used in the production of semiconductors, light-emitting diodes (LEDs) and solar panels.

The largest use of germanium is in the semiconductor industry. When doped with small amounts of arsenic, gallium, indium, antimony or phosphorus, germanium is used to make transistors for use in electronic devices.

China is the world’s largest producer of the two elements, with more than 95 per cent of the global gallium output and 67 per cent of germanium production, according to the UK Critical Minerals Intelligence Centre.

Other countries that produce gallium include Japan, South Korea, Russia and Ukraine, according to the CRU Group, a metals industry intelligence provider. Germanium is also produced in Canada, Belgium, the US and Russia.

The Trigger

The export control move by China comes after the US and its allies took aggressive steps to further tighten the choke hold on China’s chip ambitions.

In January, Dutch and Japanese officials agreed in principle to join the US campaign. Together, the three countries are the world’s top sources of machinery and have the expertise needed to make the world’s most advanced semiconductors.

As part of this, ASML, the Dutch toolmaker, in a statement on 30 June said that effective September 1, it will be required to apply for a license from The Hague to ship its most advanced immersion deep ultraviolet (DUV) lithography systems, including the TWINSCAN NXT: 2000i, and more sophisticated models.

The Europe’s most valuable tech company, is already prohibited from selling its most cutting-edge technology, so-called extreme ultraviolet (EUV) lithography, to Chinese companies.

The latest tightening export restrictions by Dutch means Chinese companies will now be forced to use ASML’s lower-end equipment – NXT1980i, which can be used for 10-nm node chips.

However, this might change under further pressure from the US, with Washington expected to impose a new rule that could even put NXT: 1980Di machine out of Chinese hands.

US Impact

The Chinese export control is latest in the country’s tit-for-tat trade war on technology with the US and Europe, with Washington being “the main target”.

The Chinese government earlier this year barred companies that handle critical information from buying microchips made by the Boise, Idaho-based Micron. The company’s chips, which are used for memory storage in all kinds of electronic devices were deemed to pose “relatively serious cybersecurity problems” by China’s internet watchdog after a review.

To understand the export control imposed on gallium and germanium, we need to see how US sources these metals.

A recent report from the US Geological Survey and Department of the Interior revealed that China accounted for 53 percent of US gallium imports and 54 per cent of US germanium imports between 2018 and 2021.

The way things stand now, it is clear that the Chinese curbs could complicate the US-led efforts to shift critical supply chains away from China.

What Next

Beijing almost certainly sees these controls as a potential bargaining chip in its negotiations with Washington to roll back elements of recent export controls on semiconductors and semiconductor manufacturing equipment.

The export control action offers a glimpse of new tactics by Beijing, which is even reflected in the State-owned media with one such publication describing Beijing’s move as “just and righteous”.

“Those doubting China’s decision could ask the US government why it holds the world’s largest germanium mines but seldom exploits them,” it said. “Or they could ask the Netherlands why it included certain semiconductor-related products, such as lithographic machines, into its export control list”.

The supply chain weaponization is a “very useful reminder” of the “urgency of de-risking from China on critical resources and as such the US and EU will have to start seriously looking at alternative sources even if that means “higher costs and/or engaging in unpopular pursuits of mining and refining at home”, said Thorsten Benner, director of the Global Public Policy Institute in Berlin.

The US already has significant deposits of germanium but has strict control on its extraction.

At the same time, it is highly unlikely that export restrictions on advanced chip-making equipment would be rolled back or curtailed as President Joe Biden’s administration heads into the 2024 elections, which only exacerbates the “deglobalisation” in the semiconductor industry.

However, some are hopeful a different path forward can be established during US Treasury Secretary Janet Yellen’s first trip as secretary to China this week, with Yellen reportedly seeking to assuage economic and trade tensions between Beijing and Washington.